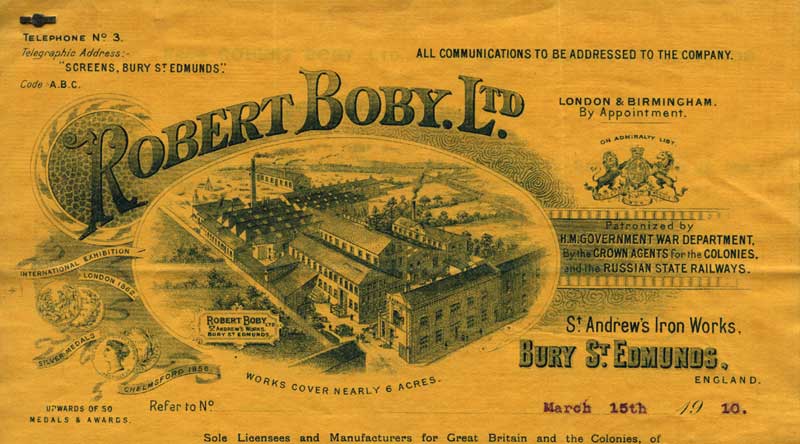

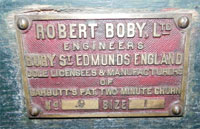

Typical Boby makers plate

Quick links on this page

Sets up as Ironmonger 1843

Sets up factory 1855

Cornish leaves Boby 1865

Boby quits Ironmongery business 1871

Station Works opened 1873

Factory Fire 1877

Robert Boby dies 1886

Becomes Limited Company 1898

Great War 1914

Bought by Vickers 1927

Foot of Page- Bobys closed 1971

|

Robert Boby Engineering

and

the story of Boby's Engineering, workshops and Foundry

|

St Andrews Castle

|

| 1816 |

It has been written and published that St Andrews Castle in St Andrews Street South, Bury St Edmunds, was built in 1815 for the Boby family. At this time, after researching the background to Robert Boby's Iron works, the facts appear to be rather different. I can find no connection between the Boby family and St Andrews Castle until the year 1865, when George Boby moved in, and lived there until his death in 1890.

It has been shown by Jane Fiske that St Andrews Castle was actually built by Ezekiel Sparke, who had been an Attorney who acted for James Oakes and others. In Pigot's Universal Directory of Suffolk for 1790, Sparke was listed as an attorney with a freehold at Hawstead. Sparke died, aged 54, early in 1816.

Ezekiel Sparke was buried at Risby on 22nd January 1816, having been born there in 1763. Oakes recorded that "my worthy friend...died... at 3 o'clock in London, (January 15th), after the Operation of being cut for the Stone." Sparke had married Sarah Sturgeon at Thurston on 21st August, 1800. Sarah Sparke would live as a widow until her death, in her 87th year, on 24th June, 1865, in Bury St Edmunds.(BNP 27th June, 1865, page 5)

Sparke may have moved in around 1795, and the Sparke family must have lived there at least until 1816. The property was advertised as up for sale in 1839, and later, St Andrews Castle was owned by Thomas Collins, solicitor and Clerk to the county council from about 1847 to some time prior to the 1861 census.

|

| 1827 |

In Robert Boby's obituary it was stated that Robert Boby was born at Standford (probably Stanford) in Norfolk on August 7th, 1814. He came to Bury St Edmunds in about 1827, when he was 13 years old and would live there until his death in 1886. (This obituary can be found in The Bury and Norwich Post of 7th December 1886.)

Further details from "Family Search.org" are that he was christened on 20th July, 1815. His father was Charles Boby, and his mother was Maria Munford. The Bishop's transcripts for 1815 include the information that other children of the marriage were baptised at the same time. These were William, born February 24th, 1811, and Elizabeth, born February 14th, 1813.

Also it is noted that Maria is described as, "Maria, his wife, late Munford-Stanford-Farmer."and signed J Wilkinson.

His brother George Boby was born on 8th June 1821 also at Stanford in Norfolk, and christened there on 21st July, 1823.

His sister Ann Boby, was born in 1817 at Stanford and would eventually marry George Stearn Mumford and they would become farmers at Lavenham. She died in 1889, on 11th January.

|

| 1830 |

William Groom was one of the 5 Ironmongers at Bury St Edmunds listed in Pigot's Directory of 1830. His address was 8 Great Market Place.

It seems that in 1830, Robert Boby joined the Ironmongery business of Mr William Groom, as an Assistant. In 1866, when he finally gave up the business, he wrote that he had been associated with that business in the Meat Market as an assistant and partner for 36 years. He would soon become Groom's partner, and would take over his business when Groom died in 1843.

|

| 1841 |

In the census of 1841 there was a Robert Boby living at the Meat Market in Bury St Edmunds. He was recorded as age 25, which might imply a birth year of 1816. He was also recorded as having been born "in the same county", ie Suffolk, not Norfolk. His profession was recorded as Ironmonger.Sh. This might indicate that he was a shop assistant at the Ironmonger's shop, or possibly a shareholder. He seems to have been living in the home of William Groom, aged 40, also described as an Ironmonger. Groom seems to have been the head of the household, living with his wife, Elizabeth, and 5 daughters, their governess, Jane Rogers, (aged 25), Boby himself, and one other male shop assistant and four female shop assistants.

Significantly, Pigot's 1839 Directory of Suffolk listed a William Groom, of 8, Meat Market, under the heading of, " Braziers and Tin plate workers". He was also listed under, "Ironmongers and Oil and Colourmen."

Robert Boby himself would later claim that he had been Groom's business partner for some years.

The 1841 census does not record as much detail as later census pages, and it is therefore harder to trace the right person. However, there was at Fore Street, in Ipswich, a linen draper, called John Roberts. There were 8 shop assistants at the same address, one of whom was a George Boby, aged 20, entered as Draper sh(?unclear) which may mean draper-shop assistant. As George would appear in the next census as a grocer and draper, it is probable that this is the brother of Robert Boby. If so, he is erroneously recorded as "born in the same county? Y".

|

|

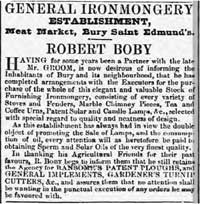

Boby sets up his Ironmongery business |

| 1843 |

Somehow, Robert Boby raised the money to buy Mr Groom's share of the Ironmongery business. In 1843, according to "Grace's Guide to British Industrial History",

Robert Boby was in business in Bury St. Edmunds as an 'Ironmonger, Red and White Lead Dealer, Brazier and Turner.'

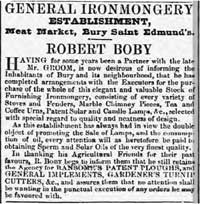

The Bury and Norwich Post of 15th November 1843 carried this announcement from the General Ironmongery Establishment, Meat Market, Bury St Edmund's.

"Robert Boby, having for some years been a partner of the late Mr Groom......has now completed arrangements with the executors for the purchase of the whole of this elegant and valuable stock."

The announcement also said that he would continue to sell the finest sperm and solar oils to promote the use of lamps. Also he would continue to hold the agency for Ransome's patent ploughs and other implements.

|

| 1844 |

In White's Directory of suffolk for 1844, William Groom continued to be listed under, "Braziers and Tinners", at 7 Meat Market, which is a next door address to that recorded by Pigot in 1839. Groom also continued to be listed under "Ironmongers" at 7, Meat Market, with a notation that stated, "& oil, white & red lead, &c dealer".

Robert Boby is not listed under these headings in this Directory. These directories are, of course, prone to error if a business changes hands without being noticed. As we have seen, Boby bought the business of the deceased Mr Groom in November, 1843.

The address of 7, Meat Market was later known as 7 Cornhill, much modernised and occupied by the Westminster Bank, and now known as the NatWest bank.

|

|

Sheldrake & George Boby partners |

|

1847 |

At the start of 1847, the Ipswich Journal carried an advertisement from Thomas Sheldrake on the 16th January. It stated that he was taking George Boby into partnership st Stowmarket. The resulting new firm of Sheldrake and Boby would combine their premises and rationalise their stock, starting with a grand sale of Sheldrake's existing inventory.

Robert Boby was a prominent citizen of Bury at this time, as shown by the following newspaper item.

The Bury and Norwich Post for 29th September 1847 announced that the list of Burgesses was to be revised by a court convened for the purpose. This was the Register of Electors, and those liable for the Poor Rate. The court would consist of the Mayor, Henry Prigg, John Battley the younger and Robert Boby, both of Bury St Edmunds, and be held from 5th to 15th October at the Guildhall. Overseers of the Poor, Vestry Clerks and Collectors of the Poor rate were required to attend to produce their lists and be questioned as to their content as necessary. The order was signed by Joseph Hanby Holmes, Town Clerk.

In the summer of 1847, Robert's brother, George Boby, married Ann Boby at Stowmarket. It seems that Boby was her maiden name as well as her married name.

|

| 1851 |

In the 1851 census Robert Boby was "Living at 7 Meat Market, Bury St. Edmunds (age 34 born Stanford, Norfolk), Ironmonger employing six men. with wife Jane (age 26 born Stowmarket, Suffolk). Three servants." This address is believed to be 7, Cornhill today.

In 1851 he was given the contract to install a gas lighting system in St James's Church.

In the 1851 census, Robert Boby's brother George Boby was living in Stowmarket at 36 Ipswich Street. He was recorded as born in Norfolk at Stanford, aged 29, married to Anne Boby, aged 20(?unclear), born in Stowupland, (?unclear) Suffolk. Daughter Sarah was 2 years old, born in Stowmarket. His profession was "Grocer and Draper", and 4 servants and 5 shop assistants were also recorded at that address.

|

|

Bridgman's Chemist shop |

| 1852 |

In the 1851 census, Thomas Cooper Bridgman and his family were living at 25 Northgate Street. He was recorded as aged 44, born at Clare, and given the occupation of Chemist. His wife, Rhoda Maria Bridgman was aged 32, of Hampstead in Middlesex. There was an 8 year old daughter called Charlotte Rhoda Bridgman, a 7 year old son called Thomas Harry, born at Lakenham (?) Norfolk, a 6 year old daughter, Mary Jane, a 5 year old son, Edward Charles, and 2 year old daughter Caroline. Mary, Edward and Caroline were all born in Bury. There were two servants.

In 1857 Eyre and Spottiswood published a patent which had previously been published at the Great Seal Patent Office in 1852. It was granted to Thomas Cooper Bridgman for the Construction of screens, riddles, or sieves, being Patent Number 1747. A Thomas Cooper Bridgman was born in Clare in 1806, and was baptised on 11th September, the son of Ann and Thomas Bridgman. He had married Mary Ann Grave on May 19th, 1828 at Great Yarmouth, which was Mary's home, and they had a daughter, Amelia Grave Bridgman.

Thomas was living in Bury at the time of their marriage. His occupation was given as Chemist, and Bridgman is also listed as a photographer at this website:

http://www.cartedevisite.co.uk/photographers-category/photographers/photographers-b/

He would die, aged only 53 in Bury St Edmunds in 1859, and was buried on 8th June at the cemetery.

|

|

George Boby takes over from Sheldrake |

| 1853 |

At Stowmarket Thomas Sheldrake died, proprietor of a Drapery business. His entire stock was bought by George Boby, also a draper, and his esrtwhile partner, who advertised an "Extensive Selling Off", of all these goods at below the cost of manufacture. See Bury and Norwich Post, 13th July 1853. Their partnership was naturally dissolved by Sheldrake's death, and was announced in the Perry’s Bankrupt Gazette for 7th January 1854. "Debts by Boby" meant that George took over all the outstanding debts along with Sheldrake's share of the assets which he paid for.

|

|

Bridgman's photographic inventions |

|

blank |

In 1853 at Bury, Thomas Bridgman invented a new way of using the collodion photographic process, as reported in the Bury and Norwich Post of 1st June, 1853.

|

| 1854 |

On 15th January, 1854, Jane Boby gave birth to a son, Walter Robert Boby, who was baptised on 22nd May at St James's church in Bury. Walter would grow up to be a civil engineer living in Bury St Edmunds, but seems to have had an on and off involvement with the growing family business of Robert Boby.

Jane Boby died soon after the birth at the age of only 29 years, leaving Robert a widower, and the infant Walter without his mother. She did not live to see the baby baptised.

| 1855 |

In 1852 Thomas Cooper Bridgman had been granted a patent for the Construction of screens, riddles, or sieves, being Patent Number 1747. Bridgman was a chemist in Bury St Edmunds and had since also received a patent for an improved photographic process. We can envisage that Bridgman might have approached Robert Boby with a view to making use of his inventions. Together they used Bridgman's new screen to build a prototype corn dressing machine. As an Ironmonger and seller of agricultural machines, Boby knew what farmers needed, and was in a position to sell to them.

In the London Gazette 1855 page 2665 is found the following official public record concerning applications for patents:

Patent Law Amendment Act, 1852.

Office of the Commissioners of Patents for

Inventions.

"NOTICE is hereby given, that—

......................

478. And Robert Boby, of St. Edmund's, Machinist,

and Thomas Cooper Bridgman, both of

the same borough, in the county of Suffolk,

Chemist, have given the like notice in respect

of the invention of " improvements in corn

dressing and winnowing machines."

As set forth in their petition, recorded in the said

office on the 3rd day of March, 1855."

In Bury, Robert Boby, who was an ironmonger on the Meat Market, now decided to set up a factory to build this newly patented agricultural machinery. Boby had been recorded as an Ironmonger, Brazier and Turner as early as 1843, and must have been of an inventive and entrepreneurial turn of mind. In 1855 he built the Improved Corn Dressing and Winnowing machine to separate corn from chaff, and won a gold medal with it at the Chelmsford Show in 1856. He decided to go into manufacturing rather than license the invention to anyone else. Presumably Bridgman would receive a royalty on each machine sold.

In the Bury and Norwich Post of 29th August 1855, it was reported that "an improved winnowing machine was exhibited (at the Royal Agricultural Society at Carlisle) by Mr Robert Boby of this town, the manufacturer and joint patentee with the inventor, Mr T C Bridgman." So here it is Bridgman who is credited with the actual invention of these improvements, and Boby who was in a position to be able to build it. The paper listed two specific improvements to existing designs but stated that it could not be submitted to a trial in Carlisle because of a rule that the machine should work at a fixed rate.

Such new and relatively heavy machinery could now be shipped easily to anywhere, home or abroad, via the railway system which covered all major ports by this time. This was to be very important for the development of industry in the town. At this time there were probably still about 300 families in Bury involved in agriculture, while the largest single source of employment was probably in domestic service. The Gas Works was the only other industrial type of work available.

Initially Boby seems to have made use of the yard behind his shop to produce his new machines. But he may well soon have been renting space in the defunct Home Maltings in St Andrews Street for some time before he finally purchased it. He did not risk buying further property until 1860. According to the Bury and Norwich Post of March 11th, 1884, the new works was located to the rear of what was then Pump Court. Pump Court itself stood by the side of St Andrews Street.

From later claims made by both men, it seems that George Cornish was employed at this time by Robert Boby to run the machinery production side, and Josiah Le Butt was employed as Boby's travelling representative. Both men would come to understand the farmers' requirements and were key elements in Boby's success in building up his factory business.

|

| 1856 |

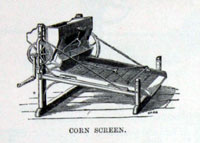

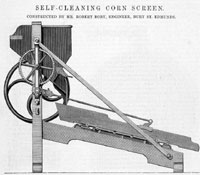

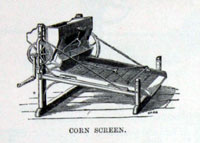

In the first full year of production, Robert Boby produced 200 Corn Screens of his and Bridgman's own design. These would become very popular and by 1887 he would sell over 13,000 units all over the world.

At the Chelmsford Royal Show of 1856, the Corn Dressing and Winnowing Machine built in Bury St Edmunds won a Gold Medal.

|

| 1859 |

Thomas Cooper Bridgman, who had probably been the main inventor of Boby's Patent Corn Screen died in 1859, at the age of only 53 in Bury St Edmunds. He was buried on 8th June at the cemetery. Robert Boby had shared the patent for the screen with him, and despite his loss, Boby would continue to make innovations and to prosper.

Robert Boby's first wife, Jane, had died in 1854. On October 22nd, 1859, he married Elizabeth the eldest daughter of the late Mr. R. Garrett of Downham Market at Mepel, Isle of Ely.

|

|

|

Silver Medal Corn Screen |

| 1860 |

Boby's Patent Corn Screen successfully competed at Norwich, in 1860, against a new patent self-cleaning and adjustable rotary screen, and obtained the silver medal. It was described as follows in its 1862 London Exhibition Catalogue for Class IX.

"BODY'S PATENT CORN SCREEN effectually separates all thin corns, stones, seeds, etc. from either barley, wheat, or sanfoin, and produces a sample that enables the merchant or farmer to obtain the highest market price for his corn. "

"To maltsters it is invaluable, as the duty on malt renders it necessary they should pay only on the best barley.

- Screen No. 2, 50 bushels per hour. £7-0-0

- Screen No. 1, 90 bushels per hour. £9-0-0

- Stone separator, extra. £1-10-0

- Screen No. 3, 150 bushels per hour. £15-15-0 "

Part of Boby's success was his constant striving for improvement, and within a couple of years this screen would be upgraded by the addition of an air blower.

In October 1860, Robert Boby was elected as one of the Guildhall Feoffees to replace Mr T C Denton (Source-Obituary).

In 1860 Robert Boby also became a Town Councillor, replacing Mr Goldsmith who had recently died (Obituary). Boby would remain on Bury St Edmunds Borough Council for many years. (He would become the Mayor in 1883.)

On 11th January 1860 Ransomes and Sim's Agricultural Implement Warehouse was opened at 10 Meat Market, Bury St Edmunds, with William Clark as resident agent. A large advertisement to this effect was placed in the Bury and Norwich Post for 3rd January, 1860.

Robert Boby now built a new warehouse at the rear of his ironmongery shop in the Meat Market. This site had probably previously been the yard behind his shop. It fronted on to St Andrews Street south, and was adorned with a stone plaque pronouncing, "RB 1860". This warehouse was later occupied by Duttons, House Furnishers, and Cramphorns. (Notes in Record Office file "Robert Boby Way cuttings", BB 5/1.)

On 31st August 1860, the creditors of James Garrod sold the Home Maltings to Robert Boby. Home Maltings had been part of the premises of the Capital Brewery (Buckley and Garnish) which had opened in 1791 and closed a year later, passing to John Clark. It then became owned by Stutter and Gallant, (1813 to 1844) and then to James Garrod, a common carrier. Garrod got into financial difficulties and the Trustees for his creditors arranged the sale. Boby paid £900, and it is interesting to note that there were three current occupiers listed in the deed, being Grayston, Burrell and Boby himself.

According to the St James Rate Book, Boby did not enter into beneficial occupation and start to pay rates on the Home Maltings until March of 1861. This may mean that there was a period when demolition and rebuilding or refurbishment was under way.

|

| 1861 |

In March, 1861, Robert Boby's expansion continued when he completed the first of his modifications to his newly acquired site known as "Home Maltings",

in St Andrew's Street South, and began to pay rates on it. Improvements continued and

new Machine, Fitting, Joiners and Erecting Shops, were soon erected which resulted in the doubling of his rating assessment within a year. This site would remain part of Boby's works right up to eventual closure in the 1970s.

In the 1861 census, Robert Boby was recorded as follows: "Living at 7 Meat Market, Bury St. Edmunds (age 45 born Stanford, Norfolk), Ironmonger and Manufacturer. With wife Elizabeth (age 38 born Downham, Norfolk) and daughter Selina (age 9 months). Four servants." The servants were a cook, a nurse, a housemaid and an errand boy.

His son, Walter Robert Boby, now aged seven, appears to be living at 6, Bridge Road, Downham Market, Norfolk, registered as a "scholar", born in Bury St Edmunds. This was the home of Louisa Munford, who at age 57, was registered as Head of the household. Her daughter, Fanny(?) Penelope, aged 31, was the Proprietress of a school, while two other daughters, Mary Ann (31) and Elizabeth, (26), were registered as "teachers". Including Walter, there were 10 scholars in residence. A cook and a housemaid completed the complement. Walter had been sent to boarding school, albeit probably one run by a relative.

Robert Boby's brother George was, at this time, trading as a Draper and Grocer employing 9 assistants, at 36 Ipswich Street, Stowmarket. He was aged 39 and lived there with his wife, Caroline A(?) Boby, born in Stowmarket and aged 41, daughter Sarah M. aged 12, and son, John W. aged 3. George was born in Stanford in Norfolk. Also noted at that address were 5 servants, and 9 shop assistants for both the grocery and drapery businesses.

One of Boby's employees or associates was Josiah Le Butt, a man who would go on to found his own iron works in Bury St Edmunds. In 1861 the only likely candidate that can be found was a Josiah Lebutt, who was an unmarried lodger aged 31, living at 10 Out Westgate, Bury St Edmunds, in the home of Benjamin Desneux, a retired compositor. However, Lebutt's birthplace is given as Folkestone in Kent, whereas in later years our man is recorded as born in Spratton in Northants. This man's occupation is given as Traveller, which does fit our man, who was a Boby's representative for some years.

|

| 1862 |

In 1862 Boby was exhibiting at the London Exhibition in Class IX, "Machines for cleaning and separating grain, and improved wort pump for brewers." It was claimed that, "Has obtained and still holds the First Prize and Silver Medal of the Royal Agricultural Society or England, and 30 other First-class Prizes.

4,000 of these machines have been sold in 5 years."

|

|

Corn Screen with Blower |

|

blank |

He showed his Patent Corn Screen, described above, and an improved version with a blower, which was described as follows:

"This is the original well-known screen, with a simple blower in front of the hopper, the blast from which acts upon the grain as it falls from the hopper to the screen. This blower is driven, with a very small additional power, from the screen spindle, and is thrown out of use with the greatest facility by removing the strap, and the screen can then be worked alone.

This addition is very important, as it enables parties to separate most of the grown kernels, with the further great advantage obtained by the fact that the thin or tail corn is as clean and free from dust, etc. as the head sample. R. B. with the greatest confidence recommends this machine to all who are interested in obtaining a faultless sample of corn."

|

|

Robert Boby Corn Dresser |

|

blank |

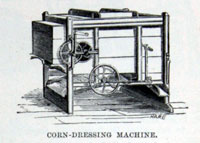

Also described and shown were:

BOBY'S PATENT CORN-DRESSING MACHINE, with patent screen combined, enables any farmer or merchant to produce a sample of wheat or barley that will command the very highest price, as all the chaff, seeds, thin corns, etc. are effectually separated from the bulk.

Corn leaving a single-blast thrashing machine, has only to pass through Boby's dressing machine once, and a perfect separation will be found to have been made. Price £15-0-0

Dressing machine, with all the advantages of the above, but without patent screen £10-0-0

|

|

Boby's Patent Haymaker |

|

blank |

BODY'S NEW PATENT DOUBLE-ACTION HAY-MAKING MACHINE.

The inventor has effected everything in the above which is accomplished by any other implement of its kind, notwithstanding he has discarded more than 30 per cent. of the parts which usually compose them. In addition to this, the arrangement is such, that the revolving forks being placed a greater distance behind the carriage wheels, the weight of the machine has passed over the grass before the fork comes in contact with it, at the same time effecting a balance which leaves little or no weight on the back of the horse.

Amongst other advantages may be named its very ready and easy adjustment, the great facility with which its action can be reversed, coupled with the greatly diminished power required to draw it, and the simplicity with which every part of it can be removed or lucubrated and kept free from dirt, while it is impossible for it to choke.

The manufacturer offers to the public an implement which is at once lighter in weight, stronger in its parts, less likely to get out of order, and requiring less horse-power than any in the market. Price £13-13

Catalogues will be sent post-free on application. "

|

| 1863 |

In 1863 Josiah Le Butt, who worked for Robert Boby had a patent taken out for: "Machinery for dressing grain. being Patent Number: 504 published: 24 February 1863". Le Butt would eventually decide to start up on his own to make some of his 'improved' machinery.

In 1863 it appears that George Boby took up a partnership with C J Tozer of the Bury St Edmunds firm of Cooper, Tozer and Co to begin a second career as a coal and seed merchant and maltster. In 1865 he would move from Stowmarket to St Andrews Castle in St Andrews Street, South. He had been a grocer and draper in Stowmarket while his brother, Robert Boby had moved from ironmongery into the manufacture of agricultural machinery, but spcialising in malt screens etc for the malting trade.

|

|

Robert Boby announces George Cornish leaving him. |

| 1865 |

On 3rd January 1865, Robert Boby placed an advertisement in the Bury and Norwich Post to announce that he was reorganising the management of various parts of his factory. The immediate cause of this seems to be that George Cornish, who had hitherto been his factory manager, had now left his employment in order to take over his father's foundry business of Cornish and Sons, to trade as George Cornish.

Railway building was still being planned despite the wide network now in place. The years between 1863 and 1866 became known as the time of Railway Mania. In 1865, Robert Boby, the Bury Engineer, and Edward Greene the brewer, set up the Bury and Thetford Railway Company to link Bury to Thetford and hence to Kings Lynn. Other directors were Peter Huddlestone, who was Greene's banking partner, and Hunter Rodwell, a barrister of Ampton Hall.

At the Royal Agricultural Society meeting at Plymouth, Boby's received a second prize for their Haymaker. The Bury and Norwich Post had made the mistake of listing this as a third prize, only to receive a rebuke in a letter to the editor published in the issue of 1st August 1865. The correspondent on behalf of Robert Boby was J Le Butt. He took the opportunity to point out that there were 18 haymakers being judged, and that if all factors had been considered it should have won 1st prize in his opinion. He concluded by saying that "if prizes are to be a standard of its excellence, we have taken more prizes for this machine in three years than all the other makers put together."

It seems that Robert Boby's brother, George Boby moved into St Andrews Castle in 1865, where he would reside until his death in 1890. He had previously been a grocer and draper at Stowmarket.

|

|

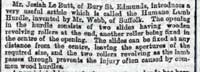

Boby and Clarke partners |

| 1866 |

In the Bury and Norwich Post of 14th August 1866, Robert Boby announced that he had taken on a partner to help him with the General and Furnishing Ironmongery Business. He had been connected with the business as Assistant and Proprietor for 36 years, and its growing size now needed more personal supervision. He introduced Mr William Clarke as his partner, who had enjoyed a personal connection with the town for 30 years. Within a few years Boby would withdraw from the Ironmongery business altogether to concentrate upon his Iron Works.

In October, 1866, Edward Greene, the brewer, gave a celebratory dinner in the Theatre Royal for 350 of his workmen and those of Robert Boby and George Cornish, the Bury Engineers. It celebrated another expansion of his Westgate Brewery. He had added a second steam engine to the brewery, a ten horsepower machine built by George Cornish. Cornish did Greene's engineering work from 1850 to 1880, while Boby's supplied malt screens and made other malting equipment and agricultural devices. All the work had been undertaken by firms in Bury, a source of pride for Greene, who had been elected as one of the town's two MP's a year earlier.

George Cornish's Foundry was in Risbygate Street, where the B & Q store is now located. Boby's Works was in St Andrews Street South, now also replaced by shops like Waitrose, and other development.

This celebratory event marked a great revival in Bury as a manufacturing town, and a new prosperity for the workers of the town. Both pub and home brewing were being rapidly replaced by brewing and malting on an industrial scale, and with the new foundries, these all gave alternative job opportunities to the poorly paid agricultural worker looking for a new start.

|

|

Le Butt's advert in Wilkin's 1867 |

|

1867

|

During 1867 the Bury firm of Wilkin and Son, of 2 Angel Lane and 16 Guildhall Street, published their "Guide to the town and Antiquities of Bury St Edmunds", with a classified list of Trades and Professions. Robert Boby appeared as usual, but his brother, George Boby, now appeared under the heading of Corn and Seed Merchants, with the annotation, "See Cooper, Tozer and Co." Cooper Tozer were located at 18 St Johns Street, and George Boby was now that firm's principal.

The London Gazette of June 21st, 1867 announced that Josiah Le Butt of the Haymaker Works in Bury St Edmunds was awarded a patent for, "improvements to hay making machines." This patent was the basis upon which Le Butt would build a new business.

Robert Boby placed an advertisement in Wilkin's Directory, as did his new competitor, Josiah Le Butt, who advertised a haymaker to rival Boby's own. Boby, however, could afford to take two pages to Le Butt's single page. Josiah Le Butt had been working with Robert Boby, firstly as a representative, and then in the factory, for some 13 years, but had now set up on his own, near the Railway Station. At first he concentrated upon his Champion Haymaker, which, he said, was a great improvement upon the Boby version, to which Le Butt had added his own patented improvements.

|

|

Josiah Le Butt's rival Champion Haymaker |

|

blank |

This advertisement in the D W Gazette for 6th June 1867, shows Le Butt taking an aggressive stance to claim a special relationship with the Boby haymaker, and also to explain his own improvements to it. Le Butt claimed that his machine to simpler to adjust, was lighter to pull, and was also stronger than the Boby original.

|

|

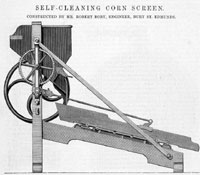

Self Cleaning cornscreen from 1868 |

| 1868 |

In 1868 Robert Boby exhibited at the Royal Agricultural Show. This shows his catalogue entry for the Self Cleaning Corn Screen, made at Bury St Edmunds. Within a few years Josiah Le Butt would set up in manufacture of a copy of the Boby machine when its patent was expected to expire.

|

|

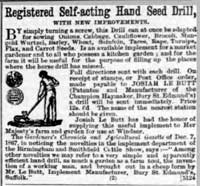

Le Butt hand seed drill |

| 1869 |

Josiah Le Butt could not simply rely upon taking trade from existing Boby designs. This seed drill was invented by a local man, and made and marketed by Le Butt since 1867. He had the distinction of it being used on the royal estate at Windsor. It was suitable for market gardens, large kitchen gardens and for use on farms to fill in any areas missed by the horse drill.

|

|

Josiah Le Butt's Lamb Hurdle |

|

blank |

Le Butt even exhibited an improved form of hurdle said to be good for lambs as it avoided damaging the animals as they left an enclosure. Invented by a Mr Webb of Suffolk, it used wooden rollers to form the exit from an enclosure, where the animals were penned.

|

|

Robert Boby 1870s |

| 1870 |

Robert Boby was now considered a pillar of the community and he had already been a councillor since 1860. He was consistently elected as Councillor for the West Ward in Bury St Edmunds. In November 1883 he would be made the Mayor of Bury St Edmunds for the year. Perhaps it was time to have his portrait taken by a photographic studio. This picture comes from the Spanton Jarman collection, held by the Bury St Edmunds Past and Present Society.

|

|

Boby leaves Ironmongers shop |

| 1871 |

In the Bury and Norwich Post 28th March 1871, it was announced that the partnership of Robert Boby, George Boby and William Clarke, trading as Boby, Clarke and Co was dissolved, and that W Clarke and co would continue their General and Furnishing Ironmongers business at 6 Meat Market, Bury St Edmunds. The partnership ended on 25th March, 1871. The Boby Brothers had decided to leave the ironmongery business to concentrate upon the Iron Works. They were also planning a new joint venture to be set up by the railway station.

In the 1871 census, Robert Boby had moved his address as follows: " Living at 17 Low Baxter Street, Bury St. Edmunds (age 56 born Stanford, Norfolk), Ironfounder and Engineer employing 123 men. With wife Elizabeth (age 46) and children Selina M. (age 10), Agnes J. (age 8), Margaret A. (age 6) and Ethel M. (age 4). Five servants. "

Robert's son by his first wife, named Walter Robert Boby, was now 17 years old and was registered as a scholar, living in at Woodbridge Grammar School. Another resident scholar at the school was Edward C Munford, aged 14, possibly a cousin of Walter. Headmaster was William Tate, aged 43, and there was an assistant master in residence and a Governess.

Meanwhile, Roberts brother, George Boby was living at 32 St Andrews Street, South, aged 49, a Corn and Seed merchant, born at Stanford in Norfolk. His wife, Caroline was 52, and they lived with their son, John William, aged 13. There were three servants. This address was otherwise known as St Andrews Castle.

The Bury and Norwich Post for the 5th December 1871 recorded a complimentary supper given at the Angel Hotel to Mr Robert Boby of St Andrew's Works, to celebrate the recent concession of the nine hours system of labour to the men by their employer. The supper was organised by a committee of the workmen, of whom Mr W Austin was chairman. Another guest was Robert Boby's brother, George Boby. "Song and sentiment was judiciously interspersed throughout the programme, and a right jovial evening was passed. The company present numbered about a hundred."

|

|

Le Butt's Cornscreen |

| 1872 |

In 1867 Josiah Le Butt had left Boby's to set up his own factory to make an improved haymaker. This was a copy of the Boby patented implement but Le Butt was able to make it because he had incorporated some improvements for which he held a patent himself.

By 1872 Josiah Le Butt was also challenging the position of Robert Boby in the corn screen marketplace. This advertisement from the York Herald attempts to cast doubt upon Boby's patent by stating that,

"This celebrated instrument was the invention of the late T C Bridgman esq of Bury St Edmunds, (hitherto known as Boby's Screen), but the Patent having recently expired, the Manufacturer Josiah Le Butt, (who for many years had a share of this Patent, and superintended the Manufacture of these machines at R Boby's Works), now gives the Public the benefit of the expiration by reducing the price by about 25 percent......"

|

|

Le Butt cornscreen at MEAL |

|

blank |

However, Le Butt was pleased to say that "Seven Thousand were in use", despite the fact that it was Robert Boby who had made these previous 7,000 screens. In 1872 he was able to make these cornscreens because Robert Boby's patent protection on them had expired.

These screens must have been strong enough to have a good long life. This one is now at the Museum of East Anglian Life, and its label states that it was used at Lavenham until 1968. As Le Butt's works closed in the 1880s the machine must have been 80 years old by the time its use ended.

S Tymms produced a new edition of "A Handbook of Bury St Edmunds" in 1872. There were numerous maltings in Bury, and the two breweries in Westgate Street, Greene's Westgate Brewery and Fred King's St Edmunds Brewery. Neither brewery employed many men. Boby's agricultural implements works in St Andrews Street employed 200 men by contrast.

|

|

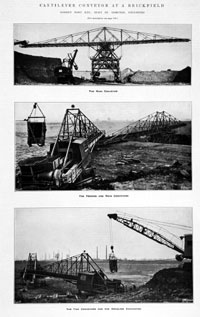

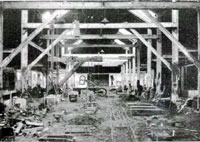

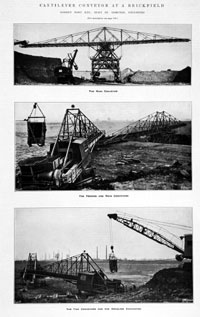

The Station Works c1873 |

| 1873 |

Robert and George Boby decided to enter a joint venture and acquire land on the Station Hill in order to set up a new factory. They would produce a variety of products for the brewing and chemical industries. Located on their own railhead, raw materials were easily unloaded, and finished bulky products easily sent to anywhere with a railway station. The picture also shows the proximity of the railway workshops to the right of the view.

The Bury and Norwich Post 4th November 1873 described a supper at the Angel Hotel given to all Boby workers to celebrate Messrs R and G Boby's Station Works opening, as well as a new building at St Andrews Works. The new station buildings were praised for their elegance, the main purpose of which was to produce brewers' finings. The raw material for this was the swim bladders of sturgeon, imported from South America. These were supplemented by the bladders from a similar species imported from Bombay. The new patented process ensured that a pint of the resulting isinglass could clarify a whole barrel of beer.

The process was long and complex involving many stages of preparation followed by eleven separate strainings. Resulting barrels could be loaded on to railway trucks at the factories own sidings and sent throughout the country. However, at this stage the full extent of the new works was not yet completed.

The Station Works also produced several other products which could also be sent out in bulk by rail. Among these were sulphuric acid, acetic acid, Bethell's patent Neutraliser and Bi-sulphate of Lime.

The St Andrews Works had supplied a 12 HP engine to drive all the machinery and pumps and would also provide power to the on-site cooperage which was in the planning stage. Another small pump was installed "at the bottom of a well at some distance" to provide a water supply. It had proved impossible to find water actually within the site.

At St Andrews Works a new Smith's shop had just been completed with 8 new forges and lathes, with a store beneath. This new shop had to be built in line with existing shafts to supply power, and thus was built on a part of the Turkey Court Yard and partly on brick piers or stilts over the old chalk pit on the site.

The hot supper included three glasses of spirits, with beer and tobacco supplied ad lib.. Robert Boby presided, his brother, George Boby, was Vice Chairman, while relatives and friends included G Boby junr, J W Boby, E Mumford etc.. Alderman Thompson gave a toast in which he referred to Robert Boby 's visit to Vienna to pursue further business connections. Robert Boby's response was that in the 12 or 14 years since "they planted their hive", they had traded with Europe, Africa, India, America and Australia. He referred to the importance of his managers, Messrs Stevens, Barton and Nunn; also to the importance of their travelling representatives, Messrs Staniland and Chapman, both abroad on Boby business. Boby also toasted his employees, especially Mr Hearn, one of his leading operatives. He said that his Vienna trip had taught him the importance of foreign relations and he had at once sent his son, (Walter) to Paris, and this was why he was absent from the occasion.

During 1873 the adjacent houses known as Turkey Court were acquired. The conveyance was dated 8th March, 1873, and the purchase price of £240 paid to various members of the Pattle family. One old matriarch, Mary Ann Pattle, aged 72, was to be paid £20 a year for life. Turkey Court was made up of 8 cottages off Field Lane, then Cemetery Road, and now called Kings Road. The site included a large garden, formerly a lime pit, 74 feet by 60 feet.

|

| 1874 |

In 1874 the Bury Free Press moved some of its offices and all of its printing into what was then called Cemetery Road. These offices, now in the re-named Kings Road, continue to be the headquarters of the BFP in 2005. The new printing press was supplied by Mr Boby's St Andrews Works, just across the road, and was powered by a steam boiler. The old presses were also moved into the new Cemetery Road works.

On page

584 of Whites Directory of Suffolk of 1874 the Boby brothers merit three entries under the alphabetical list of inhabitants.

- George Boby is listed as a finings etc manufacturer, (R & G) and corn etc merchant, (Cooper, Boby and Co.), with his home at St Andrews Castle.

-

Robert Boby is listed as a finings manufacturer, (R & G) and engineer, millwright, iron and brass founder, and agricultural implement maker, St Andrews Street south. Home at Bloomfield House, Lower Baxter Street.

-

R and G Boby were patent finings manufacturers, vinegar makers and brewers' coopers, Suffolk Cooperage and Vinegar Works, Garland Street; and Station Works, Railway depot.

It was intended that the Vinegar and Cooperage businesses would be moved to the new Station Works in due course.

Elswhere in the Directory, under the Trade and Industry heading, Cooper Boby and Co of the Station Works were listed as artificial manure merchants, also coal merchants, hay and straw dealers, maltsters, and oilcake merchants, with a Stowmarket outlet as well. Cooper Boby was George Boby's enterprise without his brother Robert, it appears.

| 1875 |

Robert Boby's son Walter was now aged 21, and to celebrate this occasion, the Bury and Norwich Post for 19th January 1875, recorded that "On Friday last, Mr Walter R Boby, son of Mr Robert Boby, of this town was presented by the workmen employed at St Andrews Works with a handsome timepiece, accompanied by an address of congratulation on the attainment of his majority. The event was celebrated the same evening by a private ball at the Suffolk Hotel, which was attended by a large party of relatives and friends."

The same paper dated 9th February 1875, recorded Walter Boby's response, which was to give a dinner at the Town Hall on last Saturday evening, for all 200 of Boby's employees. It was catered by the Suffolk Hotel's Miss Corner, reported as "a most substantial spread of boiled and roast, with plum puddings and tarts. There was a liberal supply of grog and tobacco after supper. Guests included the Mayor, (G Thomson esq) Mr Robert Boby, Mr Mumford, Mr Bridge , Mr Oliver etc.. Aftre many toasts, the health of Mr Walter Boby was drunk, and to many cheers, the foreman of the works, T Stevens,said, "They all knew the cordial feeling he (WRB) had always displayed when amongst them in the workshops, and now that he would be in the office he hoped that feeling would increase, and that he would live amongst them many years, treading in the footsteps of his father, their worthy employer."

When Robert Boby's health was drunk, his response included the following, "Until lately he did not know if his son would remain with them, or would cut out a path for himself elsewhere, but now he had decided to keep with them he trusted they would all work together for the remainder of his days."

Mr Nunn proposed a toast which included sentiments in favour of the Bury to Thetford railway, which was nearly completed.

Mr Oliver responded that with a little help they might soon be able to travel direct to Lynn. Such an extension might lower the price of coal in Bury by 2s per ton. The town of Bury was deeply indebted for its prosperity to the name of Boby for the maltings and finings works etc which had been erected at the north end of town.

Mr Sparke proposed "Success to the Station Works", and to Mr William Nunn, its manager. The evening included a number of capital songs sung by the company, and all enjoyed a very pleasant evening.

| 1876 |

By 1876 the factory of Robert Boby had expanded so much that it had completely taken over the houses of Turkey Court, partly as offices.

|

| | |

Aftermath of Boby's fire 1877 |

| 1877 |

In early 1877 Robert Boby's factory at St Andrew's Works suffered a disastrous fire and many of its buildings were lost.

The Bury and Norwich Post dated 8th May 1877, reported the "Partial Destruction of St Andrews Works." The fire started some time in the night of Saturday, 5th May, possibly in the sawdust in the saw pit near the boiler house. The alarm was given at 11.30 pm by Mr Fuller, a surgeon at the Suffolk General Hospital and Mr Edward Prior of the West Farm, who saw flames as they were returning home. They rushed to the Police Station, who roused Mr Caulfield chief of the Suffolk Alliance Assurance Office Fire Brigade. Deeks, the foreman of Alliance engine number 1, was called out at ten minutes to twelve, and went to the Police Station to collect the trolley with the canvas hose and by midnight it was attached to the hydrant at the entrance to Turkey Court, on the south side of Cemetery, (now Kings) Road. The tank at the water works was full and two other hydrants were also brought into use.

Colonel Marshall also called out the West Suffolk Militia, who made a cordon across St Andrews Street between Pump Court and the Works, in order to prevent any sightseers from impeding the firemen. Other volunteers helped Mr Stevens to rescue portable equipment from the buildings. The inhabitants of Pump Court also removed all their possessions into the centre of the quadrangle for fear of losing their homes. The militia mounted guard over them for the rest of the night.

The firemen had to concentrate upon preventing the fire spreading into Pump Court or into Frederick Ridley's leather cutting shop. Their other objective was to save those workshops at the west of the Boby premises. The large warehouse and paint shop could not be saved. A massive workshop of 150 feet long was destroyed by about half, but the Post reported that "all the most valuable portion of the plant has been preserved, the forges are untouched, and such is Mr Boby's confidence that Mr Stevens put up a notice to say that the Works would be closed until Wednesday morning when I hope to commence working."

Buildings destroyed were described as follows.

The eastern edge of the works abutted upon the western side of the quadrangle of cottages known as Pump-court, above which the ruins of the gable end were visible after the fire. From this point, running westwards, stood a warehouse 112 feet in length, 20 feet wide, and three storeys in height with a lean to shed on the south side of 13 feet in width, the eastern half of which served as a boiler house. This warehouse etc was destroyed by fire, together with contents, including a steam engine, saw benches, wheel making machinery, much timber, and also completed corn screens and dressing machines ready for delivery to customers.

Next to the warehouse stood the paint shop, 40 feet long by 20 feet wide, with an ironmomgery store below it. The paint shop held machines being painted ready for the Bath Show. Adjacent and running off at right angles was a range of offices used by the principal and his clerks. The offices formed the western boundary of a yard, which also had stables on the south side of it. The stables were saved although the roof caught fire. Otherwise, these buildings were all destroyed, although the books were rescued from the office safe.

Behind the offices further to the west was a range of workshops with a tiled roof held up by iron columns supporting 26 feet wide spans. The first part of this building contained the carpenters and wheelwrights works with shaping machines, lathes, tools and benches, which were all destroyed. The area of this building destroyed was 76 feet by 53 feet, but the firemen saved a further 150 feet.

During the fire the heat was so intense that woodwork was burnt off the engines which were standing in the yard, and the coalheap outside the boilerhouse caught fire several times. However, the Post praised the Alliance Assurance firemen, their foremen, Stannard and Deeks, the police under Mr Southgate, as well as the militia and everybody else who assisted at the fire. The total damage was estimated at £9,000, but it was insured with the Commercial Union.

Mr Robert Boby himself wrote to the paper to thanks everybody involved, particularly the militia and the Alliance Fire Office who saved the premises despite having no financial interest in saving them. Because of all this help he was able to say that there would be no stoppage of work, and all orders would be attended to, and men sent out as usual. He concluded:

"I am really at a loss to find words adequately to express the obligation I feel for the sympathy and kindness I have met with during and since this calamitous fire."

The picture at the head of this section is from a CDV, or Carte de Visite, made by the studios of J W Clarke. This format was in general use before the advent of picture postcards and derived from the older practice of leaving a visiting card when calling upon acquaintances. When photography arrived, people began to add a self portrait to their visiting cards, and soon these developed to include topographical views which could be sold to the general public. These could be collected and kept in albums as a pastime.

Plans were immediately drawn up to replace the lost premises. The old cottages of Pump Court had been rented as offices by Boby, but it was obviously a bad idea to rebuild them as they had been. So in the Autumn arrangements were made to buy the site in order to build a suitable new office block.

On 15th May, 1877 the Bury and Norwich Post and Suffolk Herald, (published every Tuesday afternoon, price twopence), described the inquest of a man who died while working in Robert Boby's Turnery.

Charles Oxborrow was 28 years old, and married with 5 children. Oxborrow and John Cook were working together on one job in the fitting shop called the "turnery", pulling a strap off the grindstone on to the rigger. Oxborrow's jacket caught in the shaft which spun him round so that his legs hit the girders. One foot was torn off and his arm much damaged. He died on the way to hospital. Boby's foreman, Thomas Stevens, said that "he was attempting to do something that is done thousands of times during the year at our place, and at the time he was standing about three feet off the shaft." The jury returned "accidental death", and a subcription was raised for the benefit of the widow and five little children, to be made to Mr Robert Double of the Friendly Societies Club and Institute in College Street.

|

|

Boby building at MEAL |

| 1878 |

The factory had to be largely rebuilt after the fire of May, 1877. The new factory buildings would survive on the site until the 1970's. The building now preserved at Stowmarket in the Museum of East Anglian Life, (MEAL), was one of those built after the 1877 fire.

|

|

Boby's new Office |

| 1879 |

Pump Court had been 17 cottages occupying three sides of a square off St Andrews Street. Following the fire it was conveyed to Robert Boby on 2nd September, 1877 for £1100 by Edmund Clayton, who had himself just purchased the site as part of a larger package of properties from the Oakes family. Boby had already been in occupation of these buildings as offices for some time. The site was cleared and these new offices, warehouse and showrooms were built. The main offices of Robert Boby's Ironworks still stand on St Andrews Street South today, but are now government offices.

White's issued a new Directory of Suffolk in 1879. By now these Directories were very well developed. The entry describing the history of Bury St Edmunds filled 27 closely printed pages.

The Iron Founders listed were:-

- Robert Boby St Andrew Street South

- George Cornish, 44 Risbygate Street

- Josiah Le Butt St Andrew Street South and Tay-fen Road

- Ransomes, Sims and Head, 5 Meat Market; and Ipswich

- Woods Cocksedge and Co, 22 Meat Market; and Ipswich

|

| 1880 |

The Bury and Norwich Post for September 28th, 1880, recorded a marriage of Walter R. Boby the only son of Robert Boby of Bury St. Edmunds to Marian Boby, the younger daughter of Henry Boby of The Ashes, Stowupland. They were married in the District of Stow in Suffolk, at Stowmarket Church, by Reverend G S Barrow.

|

|

Rear of Bloomfield House |

| 1881 |

In the 1881 census, Robert Boby had moved his address as follows: " 1 Low Baxter Street, Bury St. Edmunds (age 66 born Stanford, Norfolk), Ironfounder and Implement Maker. With wife Elizabeth (age 56) and children Selina M. (age 20), Agnes J. (age 18), Margaret A. (age 16) and Ethel M. (age 14). Also four servants and a visitor. " Number 1 Low Baxter Street was also known as Bloomfield House.

Meanwhile, his son by his first wife, Walter Robert Boby, was living at 22 Cemetery Road in Bury, aged 27, described in the census as a civil engineer. He was married to 29 year old Marian Boby, and living there with her father, who was Henry Boby, a retired farmer from Stowupland. They had two domestic servants living in.

Henry Boby had lived at Ashes Farm at Stowmarket but had moved to Bury recently. He was 64, and would die in 1887, to be buried back in Stowmarket next to his deceased wife.

At the same time, Charles Edward Munford was living at Hill Farm, Lavenham, (in Cosford Rural Sanitary District), aged 24, the son of the head of household, who was his mother, Annie Munford, a widow of 64 years old. Annie (nee Ann Boby), was listed as a Farmer who farmed 470 acres, employing 20 men and 20 boys. Annie was born at Stanford in Norfolk. Her son, Charles was listed as a Clerk, and was born in Lavenham. Ann Munford, (or Mumford) was the sister of Robert and George Boby.

Arthur G Munford his 29 year old brother, was listed as Engineer, and he was born at Cockfield, as were George, aged 33, and Ellen, aged 31, his siblings.

Their father was George Stearn Mumford, who was born in 1807 in Lavenham, Suffolk. He was baptised on 10 Oct 1807 in Lavenham, and was a Farmer of 480 Acres employing 19 men and 11 boys in 1861. He died on 30 May 1870 in Lavenham, and he was buried on 4 Jun 1870 in Lavenham. He was a Gentleman / Farmer. Parents: George Mumford and Hannah Stearn.

He was married to Ann Boby before 1845.

Josiah Le Butt was living at 60 Risbygate Street, in Bury St Edmunds, aged 49, an Agricultural Engineer employing 10 men, born in Spratton in Northamptonshire.His wife was Martha M Le Butt, aged 42, born in Methwold in Norfolk, and his daughter was Florence E Le Butt, single, aged 16, working as a governess. Florence was born in Bury St Edmunds in 1865.

|

|

Boby's by 1884 |

| 1883 |

In 1883, Robert Boby, the Bury St Edmunds agricultural implements maker of the St Andrews Works, in St Andrews Street (South), was elected Mayor of Bury St Edmunds. Boby had been a councillor since 1860, and he took over as Mayor from Thomas Ridley, the Grocer of Abbeygate Street.

At the Mayor making, his seconder, Cllr C Beard said, inter alia, that "he had never heard a man spoken so highly of by his workmen."

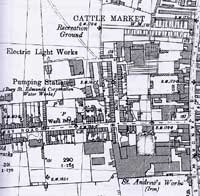

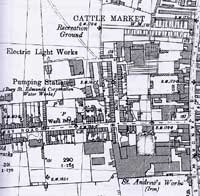

Click on the thumbnail here to see the factory in its town edge context by the time of the OS map scale 1:2500 issued in 1884. The Ordnance Survey has labelled the factory, "St Andrew's Works (Iron)". However, neither the Northgate Foundry nor the Klondyke Cottages are shown on this map, as they were not yet built.

|

|

Boby's Factory |

|

1884

|

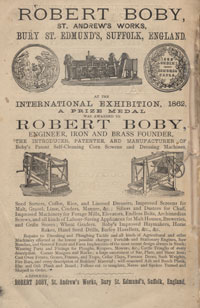

The Bury and Norwich Post reported that Robert Boby's engineering works was employing nearly 200 men in the manufacture of screening and dressing machines, hay makers and horse rakes, and most of the utensils comprising a brewers' or maltsters' plant. The St Andrews Works would also cover general engineering and foundry work of all types.

You can read this article, which was reproduced in the Jubilee History of Bury in 1887, by clicking here: (NB Use browser 'Back' button to return)

Bury and Norwich Post article, March 11th 1884

When Robert Boby's year of office as Mayor came to an end, he was elected Alderman of the town of Bury St Edmunds. He would remain on the council in this capacity until November 1886, when ill health forced his retirement.

|

| 1885 |

Booksellers, F T Groom were the publishers of the Handbook of Bury St Edmunds, written by Samuel Tymms, Honorary Secretary of the Suffolk Institute of Archaeology and Natural History. Tymms had written many learned papers on the history of Bury, and despite his death, Grooms continued to sell the latest and 5th Edition of his Handbook as Tymms' Handbook of Bury St Edmunds. They had it printed by the London firm of Spottiswoode and Co..

Robert Boby's St Andrews Works was making its famed Self Cleaning Corn Screening and Dressing Machine, having produced over 11,000 units. It had also produced 7,000 Haymakers. Mr G Cornish had "another considerable iron foundry in Risbygate Street." Ransomes of Ipswich and Woods of Stowmarket also had branches in Bury.

|

|

Robert Boby's obituary |

| 1886 |

On December 2nd 1886, Robert Boby, described as the Proprietor of St. Andrew's Works, died after a protracted illness, aged 72, at his residence in Lower Baxter Street, Bury St. Edmunds. His widow Elizabeth would continue to live at Bloomfield House until her death on January 2nd, 1899, at the age of 72.

The Bury and Norwich Post for September 28th, 1880, had recorded a marriage of Walter R. Boby the only son of Robert Boby of Bury St. Edmunds to Marian Boby, the younger daughter of Henry Boby of The Ashes, Stowupland. They were married in the District of Stow in Suffolk. Curiously, the son Walter is never recorded as living at his father's address in any census, probably because the census takers arrived while he was away at boarding schools.

It seems that Walter had finally decided not to stay in Robert Boby's business, because after Robert's death it was his nephew, Mr C E Munford, who took over the reins at the ironworks. Charles Edward Munford, (or Mumford) was the son of Robert and George Boby's sister Ann, who had married George Stearn Mumford and they were farmers at Lavenham. Ann Mumford had been a widow since 1870, and would die on 11th January 1889.

Robert Boby's funeral was held at St James's Church on 7th December, and large crowds gathered to pay their respects. The whole council and its main officers attended the service and the interment. The church was described as "comfortably filled." Although the cemetery on the edge of town had been in use since 1855, Boby was interred in the same brick vault in the old Churchyard as his first wife, Jane, who had died in 1854. Interments in the churchyard were now restricted to families who already owned vaults or graves there.

Robert Boby left a widow, a son and four daughters.

|

|

Jubilee History of Bury |

| 1887 |

In June 1887 Messrs Catling and Ranson of 8 Lower Baxter Street, Bury St Edmunds, published this "Jubilee History of Bury St Edmunds" as part of the town's Jubilee celebrations. It contained some 124 pages of Bury's past from 855 up to 1887. It is valuable to us today because of the summary of some major Bury buildings and enterprises as they were in 1887.

|

|

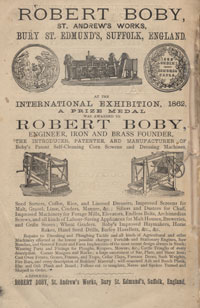

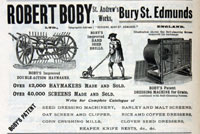

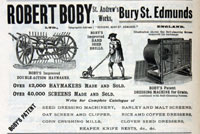

Robert Boby advertisement |

|

blank |

The St Andrews Works of Robert Boby also received a generous treatment of almost three pages of description reproduced from an article in the Bury and Norwich Post in 1884. In its first year of production in 1856 the factory produced 200 cornscreens, and by 1887 it had sent over 13,000 such units all over the world. In 1877, following a disastrous fire, nearly all the factory was rebuilt, including a new main office and showroom on the site of Pump Court on St Andrews Street. Earlier, Turkey Court had been bought and demolished to incorporate its site into the factory premises. Boby's employed 200 men in its extensive range of foundries, workshops, carpentry shops, timber yards, paintshops and stores and assembly plants, all on the one site, located in the angle between St Andrews Street and Cemetery Road, now called Kings Road.

Although Robert Boby had died since the article was written, the Jubilee History overlooks this fact.

If you have not already done so, you can read this article in the Jubilee History of Bury of 1887, by clicking here: (NB Use browser 'Back' button to return)

Bury and Norwich Post article, March 11th 1884

|

|

Death of Josiah Le Butt |

| 1888 |

Josiah Le Butt had set up his own iron works in competition with Robert Boby in 1867. In 1881 he had been recorded

in the census as an Agricultural Engineer, employing 10 men. On 4th April, 1888 Le Butt died at the early age of 57, at number 2, St Georges Terrace, which stands in Risbygate Street, Bury St Edmunds. This may well be the same location as the 1881 census address of 60, Risbygate Street. He left a wife Melinda, aged about 49, and a daughter Florence, aged about 23.

Some time after his death it is believed that the business was taken over by Boby's.

|

| 1890 |

George Boby died aged 68, born 1822, and was buried on 2nd May, 1890 at Stowmarket cemetery.

|

| 1891 |

In the 1891 census, John William Boby, described as Maltster and a single man, was head of the household at 96 Risbygate Street. He was George Boby's son, born at Stowmarket in 1857. Charles Edward Munford was a boarder at that address, also aged 34, and described as Mechanical Engineer. It seems that this is the C E Munford who had taken over the running of Robert Boby's St Andrews Ironworks. He was born at Lavenham in 1857. There were two servants.

|

| 1892 |

On 28th April, 1892, Caroline Bromley, the widow of George Boby, died at age 73, at 24 Northgate Street, Bury St Edmunds. (Ipswich Journal 30/04/1892)

|

|

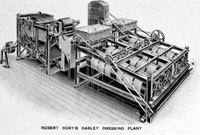

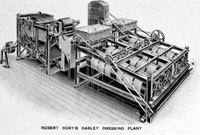

Barley Cleaning Plant |

|

1897 |

As usual, the firm of Robert Boby took every opportunity to show off its wares. This illustration, from the catalogue of exhibits at the Royal Agricultural Show of 1897, shows the Robert Boby Barley Dressing Plant. This is a far more complex piece of equipment than the simple grain cleaners produced in their early years. This piece of equipment was suitable for the large scale production of clean grain for use in the malting industry.

The company now acquired a further site expansion, buying the adjacent land known as the Pasture Ground from Emma Clarke Cockerill. This measured 1 acre 3 roods and 26 perches, more or less doubling the site area from 20th May, 1897.

| 1898 |

C E Munford had taken over the St Andrews Ironworks as Trustee upon the death of his uncle Robert in 1886. In 1898 he created a new company of Robert Boby Limited, with shares either allocated or sold to various relatives and interested parties. We do not know much about this sale, but things seem to have carried on in much the same way. It is possible that Vickers acquired some shares at this time, as their practice seems to have been to buy into associated companies, but Vickers own records do not contain such information.

The issued share capital was £10,000, and the new company was incorporated on 29th January, 1898. All the assets and real property of the old business were conveyed to the new company.

|

1899 |

It was clear that the existing foundries within the St Andrews Works could no longer keep up with demand. So during 1899 the company bought 27 acres at the Chalks, a site alongside the railway line, and through into 1900 they built the new foundry which became known as the Northgate Foundry.

The land was transferred on 1st June, 1898 from Laura Harriett Jaggard to Charles Edward Mumford.

|

| |

|

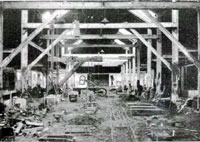

Inside Northgate Foundry |

| 1900 |

The new Foundry set up by the railway line in the Northgate area known as the Chalks was now being completed. Men had to be relocated from the St Andrews Street works, and new workers found to carry out the increased workload.

It seems that, in order to provide a convenient location for the new foundry workers, relocated from the town centre, a row of 16 cottages was built by Boby's on the hillside overlooking the foundry. These were romantically named the "Klondyke Cottages", a reference to the gold rush in the Yukon, and a name that implied hope and prosperity, a new beginning, or a new frontier.

Gradually the area became referred to as the Klondyke, and the name was later applied to the access lane to the cottages off the Beetons footpath, now called Beetons Way.

|

|

St Andrews Ironworks of R Boby

|

| 1904 |

This map from 1904 shows the location of Boby's St Andrews Iron Works west of St Andrews Street South.

|

|

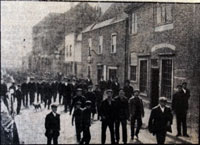

Robert Boby end of day |

|

blank |

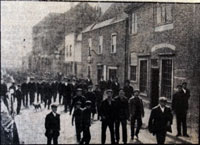

This picture shows the stream of men in St Andrews Street South after finishing work at the St Andrews Works. By 1906 there was reckoned to be about 300 men working for the Boby Ironworks, ranging from the office and stores, the paint shop, the carpentry shop and assembly rooms. The foundry work had by now shifted up to the Northgate Foundry in the Chalks area of town.

|

|

Advert from 1906 |

|

1905 |

This is a typical advertisement for the wide range of agricultural items made by Robert Boby Limited around 1905 and 1906. The seed drill, visible in the centre of the advertisement, looks like that previously made by Josiah Le Butt. Le Butt's business was bought out by Robert Boby some time in the 1880s.

|

|

Guide 1906

|

| 1906 |

During 1906 Edward J Burrow of Cheltenham was producing Number 37 of his series of Borough Guides, called "A Guide to Bury St Edmunds". It contained a potted history of the borough, together with a description of its churches, public buildings and local seats of the gentry. To the local historian its major importance is the attention paid to the advertisers within it. Burrow offered them as many pages they cared to take, and if they wanted photographs included, then Burrow would have them taken if none already existed. Boby's engineering works had eight pages devoted to it, with the title, "A Notable Bury St Edmunds Manufactory". The article included one illustration and three full page photographs especially taken by the firm of Burrow.

Boby's was credited with employing upwards of 300 men, and selling over 40,000 of one type of machine. It's malt cleaning machinery was commended, as was their patented barley dresser.

By this time the foundry at St Andrews Works has become inadequate, and a new foundry had been built behind the Northgate Railway Station. This site is today occupied by the Anglian Lane Trading Estate.

|

|

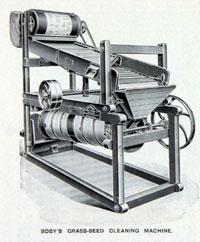

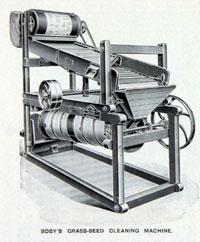

Boby's Grass Seed Cleaner |

|

blank |

Agricultural machinery of all sorts had won Robert Boby worldwide customers and over 50 medals and awards. This illustration shows how the idea of a grain cleaner could be extended to grass seed, thus opening up a new market by applying well tried ideas to other fields.

You can examine the entries about Robert Boby in this guidebook by clicking here: The 1906 Borough Guide - The Boby pages A later edition of this guide, or a reprint, has the name of the booksellers F T Groom and Son of 17 Abbeygate Street, in Bury St Edmunds, on the front cover.

|

|

Boby/Garbutt Two minute churn |

| 1908 |

In 1908 Robert Boby acquired the rights to manufacture Garbutt's Two Minute milk churn for Great Britain and the Colonies. It was claimed that it was no longer necessary to churn milk by hand for half an hour or more to make butter. The new milk churn claimed to take only two minutes to do the same job, and according to the "Farm and Station" for 1st July, 1908, it had met with great favour from English dairymen.

At Norwich the Steward and Patteson brewery was modernising and gave a large order to Robert Boby's factory. It was the largest system for pneumatic malting to be installed in the United Kingdom, and Boby's manufactured all the machinery for it. (Steward and Patteson's Pockthorpe brewery would survive until 1967, when it was taken over by Watney's. Watneys closed Pockthorpe Brewery in 1970, and the site is now largely housing.)

|

|

Boby Brothers supply coal |

| 1909 |

Because of the convenient position of their finings and chemical works next to the railway station on Station Hill, the Boby brothers dedicated railway spur made it an ideal location for the importation of coal. In an arrangement with Chapman's for local distribution, this advertisement shows the firm's venture into the coal business.

In 1909 Boby's won the contract for the supply of coal to the nearby municipal electricity works. (Record Office deed EE500/26/12).

|

|

Boby's cricket team 1912/13 |

| 1912 |

This picture of Boby's cricket team, dated 1912 or 1913, was sent in to the Bury Free Press by a reader. It was published in that paper on 12th December, 1975.

|

| 1913 |

By this time Boby's had made a significant agreement with J A Topf and Soehne, German malting engineers, to build their advanced equipment in this country.

A new barley store and Topf drier was erected for Greene King in Sparhawk Street, with the Bury firm of Boby's providing the machinery. Other improvements were probably overdue at the brewery, but the coming of the Great War would stop all further progress.

Boby's had also obtained the right to manufacture the "Galland" malting drum, which they would develop and improve as a means to produce green malt. Developments like these would gradually cause the demise of the much older malting process known as floor malting.

|

|

Vickers Machine Gun |

| 1914 |

In times of war many factories had to convert to munitions production. The agricultural engineers, Robert Boby of St Andrews Street, were sub - contracted to Vickers Sons and Maxim for this purpose. Often it was kept secret what the parts they made would be used for. After the war the link to Vickers would continue.

Vickers Sons and Maxim's made a vast array of armaments, including their Vickers Machine Gun, which had been developed from the design of Hiram Maxim after they took over the Maxim Nordenfelt Company in 1896. Unfortunately while the German army had massively equipped itself with machine guns in the years before the Great War, the British army had felt that it was not right to deploy such a weapon in a European theatre. The example shown is painted in typical colonial camouflage. The army would soon have to try to make up the shortfall on the western front.

|

|

Kings Road Corner |

|

1915 |

The German Army received its new P-class Zeppelins in April, 1915 and undertook the first raids. Erich Linnarz, its Captain, commanded LZ 38 on a raid over Eastern England on the night of 29th / 30th April. (The designation prefix 'LZ' denoted German army Zeppelins. The German navy Zeppelins were designated with the prefix 'L'.)

The LZ 38 was brand new and was 536 feet long, with a crew of 22. It had four engines and could carry two tons of bombs at a top speed of 60 mph. That night it had crossed the coast and bombed Great Yarmouth, moved south to Ipswich, dropping only a few incendiaries there. Two houses were burnt out at Ipswich but there were no casualties. The LZ 38 then followed the A45 towards Bury St Edmunds.

Bombs were dropped across Bury St Edmunds town centre, but St Andrews Works was relatively unscathed. Nevertheless there was a very near miss when the attack moved to St Andrews Street, and Kings Road was hit. An Auction Room and warehouse at the corner of Kings Road and St Andrews Street, known as St Andrews Hall, was badly damaged. Next door were stables, also set on fire. Both premises belonged to James Pettitt, a motor engineer and corn merchant. The rebuilt premises are the home of Denny Brothers today. One bomb just missed the hospital, but more damage was done in St Andrews Street.

|

|

Broken plank |

|

blank |

This picture shows a plank at Robert Boby's engineering works which was smashed by a bomb, which then rolled harmlessly away.

It is sometimes suggested that Boby's works was the target, but only because of its proximity to the damage. In the Great War the factory turned to munitions production, possibly, at first, under contract to Vickers, Sons and Maxim, the giant conglomerate with large interests in armaments. The company was probably well aware of the need for security and maintained a better blackout than the rest of the town.

In May, 1915, Mr S Allingham of the firm of Robert Boby Ltd, attended a meeting in London with 18 other East Anglian manufacturers. The meeting was called by Mr Sanders, of Davey, Paxman and Company, to hear from the War Office what was expected from the area in the manufacture of munitions of war. This resulted in the formation of the East Anglian Munitions Committee, who would negotiate contracts with the War Office, and allocate production to those companies willing and able to undertake the work. The first contract was agreed in June, 1915, for 200,000 18-pdr shells, at 22/- a shell for the first 20,000 and 20/- a unit thereafter, to be delivered within six months. A central depot was to be erected at Ransomes and Rapier of Ipswich, to receive products for varnishing and finishing, and delivery to the government. Most of the organising of this whole operation was led by Mr F H Crittall, of the Braintree firm of the same name.

Using this approach, East Anglia was the first co-operative area to deliver 18 pounder shells to the new Ministry of Munitions. Firms totally unfamiliar with making munitions, presumably including Boby's, were provided with advice, drawings and materials. The firm of E R & F Turner of Ipswich provided the necessary machine tools to make many of these shells. They produced "single operation lathes and tools, which made it possible to to employ women and unskilled workers with marked success." (Note that the exlosive contents were loaded elsewhere, at specialist explosive manufacturers.)

|

|

Miss B Barber at Boby's 1916 |

|

blank |

On 26th July 1915 the firm of Robert Boby wrote to the Secretary of The Women's Social and Political Union, asking to be provided with women suitable for working lathes and drills, to be paid at ordinary rates and accommodated and supervised by the Women's Social and Political Union. A copy of this letter is held in the Lloyd George Papers in the Parliamentary Archives, reference LG/D/11/2/11. David Lloyd George was Minister of Munitions, from 1915 to June 1916, and the prefix LG/D refers to his papers during this period. He would become Prime Minister from December 1916 until 1922.

(The Women's Social and Political Union (WSPU) was the leading militant organisation campaigning for Women's suffrage in Great Britain, 1903–1917. Its membership and policies were tightly controlled by Emmeline Pankhurst and her daughters Christabel and Sylvia. Soon after war broke out, the WSPU

abandoned its suffrage campaigns in favour of a nationalistic stance, supporting the British government in the war effort. They maintained a register of women who wanted to work, and allocated them to appropriate employers for war work.)

It seems likely, therefore, that at least some of the 18 pounder shells were made at Boby's factory in Bury St Edmunds. This was quickly followed by a contract to make 4.5 inch shells, and Robert Boby was one of the seven firms allocated a share of this contract. These firms together produced over a million 4.5 inch shells, but even this this number was limited at times by shortages of materials, brass in particular.

|

|

Soldiers at Boby's WWI |

|

blank |

Here we see one of Boby's lorries at St Andrews Ironworks together with soldiers thought to be Army Service Corps, 259 Company. If so, this company was raised in February 1915, as part of the 15th Scottish Division. ASC 259 Company specialised in motorised transport. This rare picture is from a postcard sold on EBay for £62 in June, 2014. Once Boby's were producing shells, they needed to be transported to the Munitions Committee Central Depot at Ipswich for finishing and inspection. With the transport shortage, it may well be that the army undertook to ferry shells to the railway station for onward transmission to Ipswich, where the Committee Depot had its own sidings.

The original 18 pounder contract was followed by others and the area of Norfolk, Suffolk and Essex produced over 2.1 million of this calibre. Of the 42 Boards of Management in the country, East Anglia came 3rd in the amount of total munitions output, following London and Manchester. Many other direct contracts wer executed between local firms for the Admiralty, War Office and Ministry of Munitions outside the committee's remit. These included mines, paravanes, submarine engines, motorboats, boilers, searchlights etc, all needed for the war effort. As yet I have not been able to tie any of this production with Robert Boby's.

One other Bury firm was recorded as undertaking work for the East Anglia Committee, and that was T H Nice and Co.

|

|

74/75 Mill Road |

| 1916 |

On the night of 31st March and 1st April, 1916, the Germans launched a major air attack on targets on English soil.